does brinell hardness test for stress|brinell hardness test example : agent Brinell Hardness Test was the first used and is a widely accepted hardness test. In this article we are going to dig a little deeper into explaining the Brinell Hardness Test. J.A. Brinell proposed first proposed the . webMirko Suarez 5 months ago Uploaded to My 4shared. File type apk. Size 32,524 KB. BRTV2-release-4.9.2-2005131712 - download at 4shared. BRTV2-release-4.9.2 .

{plog:ftitle_list}

webThe Central Plaza is one of the best anchored shopping malls in São Paulo including: Pernambucanas, Riachuelo, Renner, Lojas Americanas, Cinemark, Loja Pirueta, McDonald's, Centauro, Casas Bahia, Lojas .

Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell . In the manufacturing industry, we are measuring the hardness of the metal by various hardness tests and one of them is the Brinell Hardness Test. In this article, we will see its performing methods, advantages, .The Brinell test is frequently used to determine the hardness metal forgings and castings that have large grain structures. The Brinell test provides a measurement over a fairly large area .

Brinell Hardness Test was the first used and is a widely accepted hardness test. In this article we are going to dig a little deeper into explaining the Brinell Hardness Test. J.A. Brinell proposed first proposed the .ii Brinell hardness test. In the Brinell hardness test, a load of 29.42 kN is applied using a 10 mm tungsten carbide ball. The indentation created is measured optically, and the hardness is .The Brinell hardness test measures surface hardness by creating an indentation on the material's surface with a hard sphere under a specific load. The size of this indentation reflects . Non-destructive Brinell hardness measurements in situ, and tests of their chemical composition and microstructure, allow for a safe assessment of the strength properties of steel .

The Brinell method is a static hardness testing method, which can be characterised as follows: It is one of the standardised procedures (ISO 6506, ASTM E10). The Brinell method has a .The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear .Brinell hardness of Gold is approximately 190 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of .Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table . Brinell Hardness: Rockwell Hardness: Tensile Strength (Approximate) Psi: Tungsten Carbide Ball 3000 KG: . Beam Deflections and Stress Bearing Apps, Specs & Data Belt Design Data Calcs Civil Engineering Design & Manufacturability Electric Motor .

Abstract. There exist various types of experimental measurement of hardness, yet a unified understanding of various hardness measurements lacks. Here, by testing the hardness of a wide range of materials, we show that Rockwell and Brinell hardness tests, the two most used hardness measurements, are closely related. The experimental .Brinell hardness of Titanium is approximately 700 – 2700 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly .

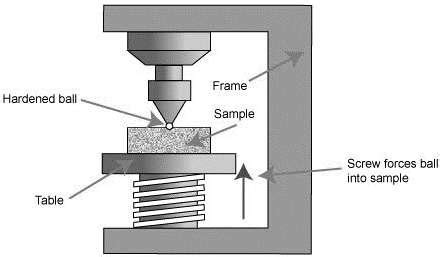

Stress-strain curves are an extremely important graphical measure of a material’s mechanical properties, and all students of Mechanics of Materials will encounter them often. However, they are not without some subtlety, especially in the case of ductile materials that can undergo sub- stantial geometrical change during testing. 5.2 Brinell Hardness Test. In the Brinell hardness test, the test material is indented by use of a 10-mm-diameter hardened- steel/carbide ball that is subjected to a specified load, F (see Fig. 3.6). For hard materials, the full load of 3000 kgf is applied; whereas for softer materials, the applied load is in the range of 500–1500 kgf.Brinell hardness of Titanium is approximately 700 – 2700 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly .

Brinell hardness of Gold is approximately 190 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small .Does it ever cross your mind how the assessment of a material hardness test is interpreted? Concluding a hardness test using a popular method like the Brinell hardness test requires measuring the indentation left on the material surface by the load applied. Though several other hardness testing methods are available, the Brinell hardness test and how to read and .The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .

In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . Stress (σ) can be equated to the load per unit area or the force (F) applied per cross-sectional area (A) .

Shear stress, τ Shear strain, γ Fracture Shear strength Yield point θ 12 Hardness • Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg • Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. • Vickers Hardness Test: Pyramid shape indenter ()( 2 2 ) 2 Db Db Db Di F HB − − = π .

Brinell hardness of Aluminium is approximately 240 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for .Common indentation hardness scales are Rockwell, Vickers, Shore, and Brinell, amongst others. Rebound hardness . Rebound hardness, . which involves iterative FEM modelling of an indentation test, does allow a stress-strain curve to be obtained via indentation, but this is outside the scope of conventional hardness testing.) A hardness number .The Brinell hardness number (BHN) is defined as the stress P/A, in kilogram-force per millimeter square, where P is the load and A the surface area of the spherical cap forming the indentation. . The hardness of steel, wood and concrete is tested by pressing-in method. For example, Brinell Hardness (HB) test is expressed by the pressure .

vehicle crash test side impact

Standard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg is applied to the surface of the material for a longer duration, typically 15 to 60 seconds.Brinell hardness of Aluminium is approximately 240 MPa. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for . The Brinell Hardness Test is a straightforward process that is often applied to materials with rough structures, like cast irons or forged metal samples. During the test, a 5mm or 10mm round carbide ball is pressed into the material using a very high test load, usually between 750kg and 3000kg. This action creates an indentation that is .

Brinell Hardness Test. Brinell hardness is determined by forcing a hard steel or carbide sphere of a specified diameter under a specified load into the surface of a material and measuring the diameter of the indentation left after the test.The Brinell hardness number, or simply the Brinell number, is obtained by dividing the load used, in . The Brinell test introduced the production phase of indentation hardness testing and helped pave the way for other, more relevant hardness testing methods. And although the Brinell hardness test was the first widely used hardness testing method, it still has its use in today’s manufacturing and engineering. Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method . The tests showed that the state of stress of steel structure elements has a significant impact on the results of hardness measurements (in situ). . Metallic materials – Brinell hardness test – Part 1: Test method. Google Scholar [6] Błażewski S., Mikoszewski J., Pomiary twardości metali (Metal hardness measurements). Warszawa .

Applications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela-tively soft materials, including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter and high load helps to minimize the effect of surface irregu-larities and yields more accurate hardness values. Soft Materials .Young’s modulus is equal to the longitudinal stress divided by the strain. Hardness of Titanium Grade 2. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

brinell hardness tester diagram

brinell hardness test theory

両替. See Also in Japanese. 両替機 noun. Ryōgae-ki money changer, money changing machine. See Also in English. exchange noun, verb.

does brinell hardness test for stress|brinell hardness test example